Home › Forums › All Things 750 Twin › Technical Garage › How To Fix It › Swing arm bushes

- This topic has 14 replies, 2 voices, and was last updated 3 years, 2 months ago by

Kaptainkwak.

Kaptainkwak.

-

AuthorPosts

-

1st February 2021 at 12:12 am #27292

BevanParticipant

BevanParticipantHi, has any one got any tips for getting the bushes out of each end of the swing arm? I can’t seem to get the central sleeve to move off centre and then get a bar in to drive out the sleeves. Cheers Bevan

1st February 2021 at 1:09 am #27293 KaptainkwakKeymaster

KaptainkwakKeymasterI assume you have tried heating the swinging arm? If they are that stuck I would suggest to cut a slot across the end with a hacksaw. Then carefully extend the slot inside as far as you can with a hacksaw blade and a dremel. This will reduce the pressure of the bush and allow you to knock them out.

KK

2nd February 2021 at 12:47 am #27294 BevanParticipant

BevanParticipantNo haven’t tried heating the swing arm so will try that. Battery acid has dribbled all over the swing arm so I have to do some repainting anyway. Will also try the hacksaw cuts. The residual problem is getting some ‘edge’ on the inner end of the bush in order to drive them out. On my Z1 the central collar or sleeve was easily pushed off centre to expose enough of the bush end to get a bar against and drive out the bushes. Will keep pottering.

2nd February 2021 at 5:01 am #27295 BevanParticipant

BevanParticipantI have re-read the Service Manual umpteen times and maybe I have misunderstood the construction. Manual says, “pull out the swing arm sleeve” before removing the bushes. Does the “sleeve” accupy the full width of the swing arm, sitting inside the bushes at each end? If this is the case then my “sleeve” is seized in the bushes as it doesn’t want to come out. How do I get the sleeve out?

2nd February 2021 at 8:48 am #27296 KaptainkwakKeymaster

KaptainkwakKeymasterI assumed you had removed the sleeve. This should drive straight out either way. They can seize if not greased up. Again heat should assist if it is seized. You need to make sure the bush is against something solid but not blocking the end of the sleeve then drive it through from the other end.

3rd February 2021 at 7:14 pm #27300 BevanParticipant

BevanParticipantFinally got this sorted, what a mission. Understanding the actual construction of the swing arm bearings obviously helped. I tried driving the inner steel sleeve in one direction but cast bush at that end just moved with the sleeve after shearing off the bush flange and threatened to disappear in to the swing arm. Then tried driving the sleeve from the other side, that bush flange also broke but the bush stayed put as sleeve and other bush finally emerged from the swing arm. This took some serious hammering! The binding between sleeve and bushes is surprising as it looks like the sleeve is steel and the bushes look like cast iron. Maybe water has got in at some stage as I had had to drive the swing arm bolt (rusty and white corrosion) out to initially remove the swing arm. WARNING, keep those swing arm bushes (needle bearings from ’78 I think) greased!

3rd February 2021 at 9:32 pm #27301

3rd February 2021 at 9:32 pm #27301 KaptainkwakKeymaster

KaptainkwakKeymasterWell I will stand corrected if I a wrong but to the best of my knowledge the swinging arm bushes have always been brass. The replacement ones definitely are and I see no reason to have made them in cast iron. It certainly looks like you had a job on your hands there but the main thing is you got them out.

You are right about B3 onwards being on needle rollers. One way to tell is that the B1 and B2 have a grease nipple in the swinging arm. It is important that this be re greased when serviced to prevent seizure such as this.

I would recommend you get the broken bush removed from the sleeve and completely clean and recover the it. These are very hard to find. Bushes are still available and I can supply them if you wish, just let me know.

KK

4th February 2021 at 8:55 pm #27314 BevanParticipant

BevanParticipantYou got me thinking, as I had expected brass, or even just steel. Went and had a closer look and remembering my high school metal work classes, put it to the grinding wheel – fine short sparks that ‘exploded’ in little bursts after leaving the wheel – pretty sure that’s indicative of cast iron. Have attached photo of granular texture at fracture and grind marks. Now my B1 has a fairly early chasis number, KZ750B000648. I know with my 1973 Z1 several parts were modified or changed during the first year of production, especially in the early stages of the production run. Sometimes Kawasaki also changed the part number when this happened, sometimes not. Maybe they started using cast iron bushes (high carbon content should resist seizing but obviously didn’t) then changed to brass and possibly left the part number unchanged? I managed to get one NOS bush from my local supplier, Plenter NZ, another one from Ebay, so it will be interesting to see what turns up, iron, brass or one of each. Also found a NOS sleeve on Ebay so snapped that up as well. Cheers

4th February 2021 at 10:24 pm #27315

4th February 2021 at 10:24 pm #27315 KaptainkwakKeymaster

KaptainkwakKeymasterThat is really interesting. I will look into that but keep me updated on your progress. If all else fails then I can supply brass ones for around £20 if I remember correctly.

KK

5th February 2021 at 4:11 am #27322 BevanParticipant

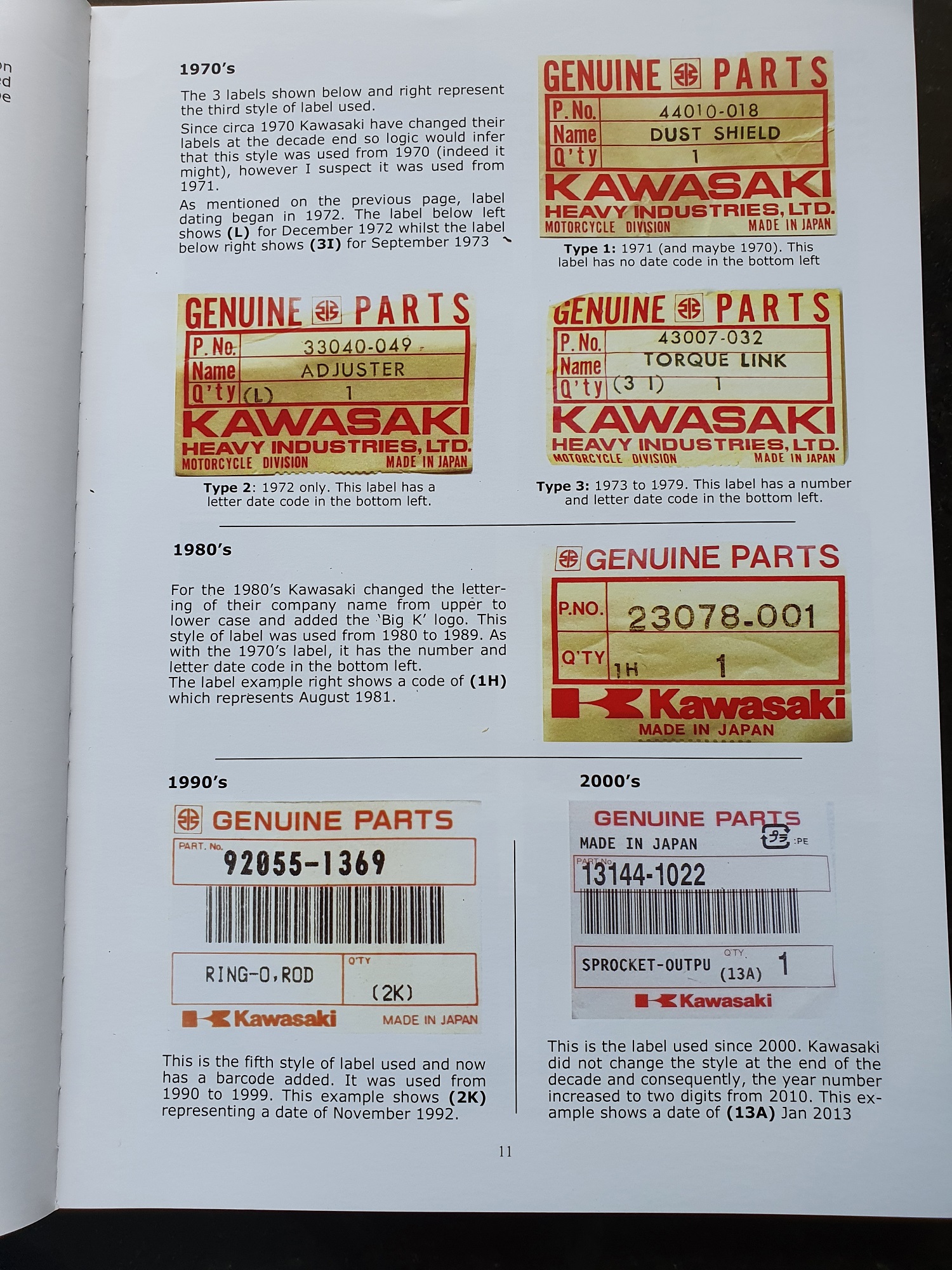

BevanParticipantKK, the first NOS bush has arrived and debunks my theory about the material changing in the first year of manfacture. It came wrapped in oily plastic (as in the photo) and then in its own sealed bag with the label. From the type style on the label and the (9J) bottom left hand side, we can determine that this part was made in October 1989, and it ain’t brass. Are the brass ones you have OEM or aftermarket? Tracking this stuff down is fun and detracts from the bottomless pit we keep throwing our money in to to get these old girls ship shape again.

5th February 2021 at 1:27 pm #27323

5th February 2021 at 1:27 pm #27323 KaptainkwakKeymaster

KaptainkwakKeymasterWell I stand corrected. I cannot see any reason why cast iron would be used in this way but it does explain why some members are having so much trouble removing old ones. It’s not very often I’ve needed to replace these. When I recently Refurbed my B1 I used a NOS swinging arm so didn’t need to remove them.

The one’s I am offering in brass are aftermarket parts and in my opinion that if nothing else is an upgrade.

Just for the record (9J) is October 1979, 1989, 1999 or 2009 as they changed the label style each decade and re-used the letter designating the year. The label on the part you have was used in 1979.

I’ve checked the prices today and they are at £30 posted for a pair.

Let me know if you need them.

Cheers

KK

-

This reply was modified 3 years, 2 months ago by

Kaptainkwak.

Kaptainkwak.

5th February 2021 at 9:15 pm #27331 BevanParticipant

BevanParticipantKK, all good, will go with OEM’s. I think the same bushes were used on other Kawasaki road bikes of the time, particularly the triple two strokes. I think cast iron was used because it is probably cheaper than brass and was a common bearing material as it can be used with a hardened steel shaft due to the coefficient of friction being relatively low, cast iron having 2 to 4% carbon. The cast iron glazes over therefore wear becomes negligible. However it is prone to rusting and hence the drama getting them out if stuck to the hardened steel sleeve.

I had interpreted the label on my NOS bush as having the ‘Big K’ logo and lower case company name, as being a 1980’s style used from 1980 to 1989 – a 1979 label would not have had the logo and KAWASAKI would have been in upper case (type 3 in John Brookes book). Cheers

5th February 2021 at 10:34 pm #27336 KaptainkwakKeymaster

KaptainkwakKeymasterThat’s are correct and fair enough re the bushes mate.

However regarding the labels this is becoming a bigger discussion ha ha. I assume you are referring to the following extracts

I am not 100% convinced he is correct with his dates. The change from upper case to lower case took place in 1979 which can be seen in the B3 to B4 model changes. I cannot see Kawasaki still making and supplying these bushes 5 years after production was ceased. Again maybe I’m wrong with that.

5th February 2021 at 10:44 pm #27337 BevanParticipant

BevanParticipantYes that’s the reference I used. It can get a bit annal, the chapter on date codes that appear on the actual parts goes on for pages. Must confess that I photographed every dated part during my Z1 resto as there are only a few parts on that bike that are not original/genuine OEM so hopefully it will help the kids make a fortune when they come to sell it, after I croak! Cheers

5th February 2021 at 10:48 pm #27338 KaptainkwakKeymaster

KaptainkwakKeymasterKinnel we sound like a complete pair of anoraks. Sad as it may be I do enjoy this knowledge. It is surprising just how much mindless Sh*t is in my head at times but it’s good to share mate.

-

This reply was modified 3 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.