Home › Forums › All Things 750 Twin › Projects and Progress › New Projects › Kaptains Log – The story of my B1

- This topic has 30 replies, 7 voices, and was last updated 3 years, 2 months ago by

jimmyjaz.

-

AuthorPosts

-

22nd July 2020 at 12:01 am #25805

KaptainkwakKeymaster

KaptainkwakKeymasterAs some of you know during the Covid19 lockdown I decided to utilise my time at home by refurbishing my B1. She is a UK registered B1 that I have owned no less than 4 times. When I have sold her it has always been with 1st refusal if selling on and as a sucker for these bikes I could never refuse. I last bought her back on 29th March 2014 and this time she is going nowhere. She had been sat in my garage for 6 years so not before time I decided to start.

22nd July 2020 at 12:06 am #25811

22nd July 2020 at 12:06 am #25811 KaptainkwakKeymaster

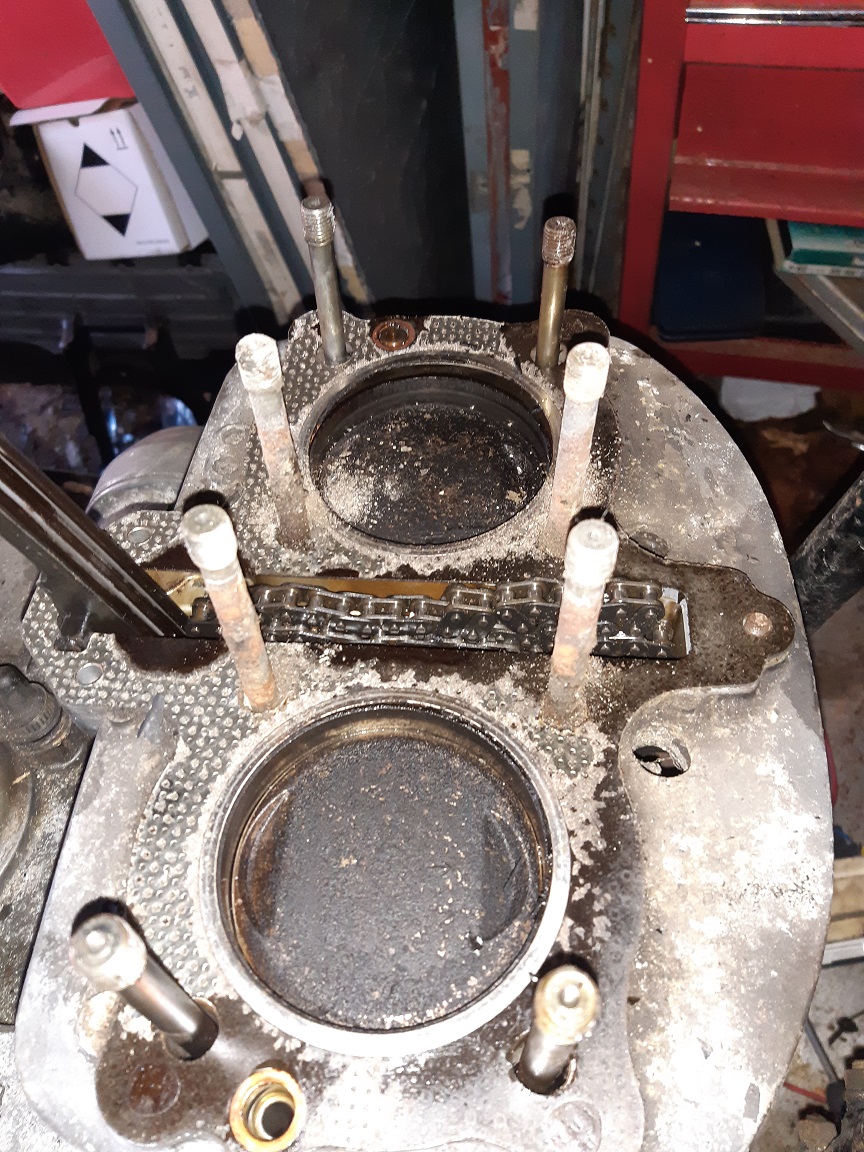

KaptainkwakKeymasterAs you can see she was very tired and in desperate need of some serious TLC. I did attempt a makeover a couple of years ago and although she did run I soon realised she need the full works.

-

This reply was modified 4 years ago by

Kaptainkwak.

Kaptainkwak.

22nd July 2020 at 12:09 am #25821 KaptainkwakKeymaster

KaptainkwakKeymasterLet’s go then . . .

She was so run down both inside and out but I got the engine stripped and out then the frame stripped bare.

-

This reply was modified 4 years ago by

Kaptainkwak.

Kaptainkwak.

22nd July 2020 at 7:45 pm #25830 KaptainkwakKeymaster22nd July 2020 at 7:49 pm #25837

KaptainkwakKeymaster22nd July 2020 at 7:49 pm #25837 KaptainkwakKeymaster22nd July 2020 at 8:36 pm #25838

KaptainkwakKeymaster22nd July 2020 at 8:36 pm #25838 coleighfParticipant

coleighfParticipantA true labour of love! I know the feeling.

22nd July 2020 at 11:52 pm #25844 KaptainkwakKeymaster22nd July 2020 at 11:54 pm #25849

KaptainkwakKeymaster22nd July 2020 at 11:54 pm #25849 KaptainkwakKeymaster23rd July 2020 at 10:35 pm #25860

KaptainkwakKeymaster23rd July 2020 at 10:35 pm #25860 KaptainkwakKeymaster24th July 2020 at 9:59 pm #25869

KaptainkwakKeymaster24th July 2020 at 9:59 pm #25869marksav

ParticipantVery nice work ! Good to see a lot being done at home instead of “contracting “ it all out .

25th July 2020 at 10:11 am #25882 KaptainkwakKeymaster25th July 2020 at 10:18 am #25890

KaptainkwakKeymaster25th July 2020 at 10:18 am #25890 KaptainkwakKeymaster25th July 2020 at 10:58 am #25891

KaptainkwakKeymaster25th July 2020 at 10:58 am #25891 coleighfParticipant

coleighfParticipantI was wondering what fertiliser you used in that plant box? When I tried that with Tomorite everything came out red!

The wiring refurb is interesting. The only time that my B1 stopped on me was in France. A fuse had blown, I replaced and it went again. What had happened was that when I fitted the Oxford cockpit fairing, I had to remove the headlight unit, disconnect it, fit it into the fairing and then re-connect. That meant that the wires were pulled forward a few inches and one of them was rubbing on the edge of the hole that the loom passed through in the back of the headlamp shell. It had chafed through the insulation and shorted out. Some insulation tape fixed it. I hadn’t previously noticed that there was no rubber grommet in this hole as there has been on every British bike that I’ve ever owned. If there had been it would never have happened. It had never occurred to me to look there when I fitted the (excellent) Cockpit fairing, which was similar to that fitted to the BMW R90S.26th July 2020 at 7:26 pm #25905 KaptainkwakKeymaster

KaptainkwakKeymasterThat is a trade secret Coleighf . . .

Cylinderhead and barrels had returned from the blasters so now time to attack the engine starting with the cut stud. I took to 2 engineering firms who both failed to remove the stud. I was looking at spark erosion when my son-in-law offered to do it. He assured me he had the skills and even came to my house with hand tools and demonstrated his expertise. 2 1/2 hours later . . .

New stud fitted and spare barrels and head were fitted ready for me to try my soda blasting

26th July 2020 at 7:37 pm #25910 KaptainkwakKeymaster

KaptainkwakKeymaster -

This reply was modified 4 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.