Forum Replies Created

-

AuthorPosts

-

29th June 2020 at 11:35 pm #25705

Doctorot

ParticipantNot a problem area for a stock engine, but for the brave souls going for bigger power its a small difference that might prevent the rod from creating additional crankcase breathing.

18th June 2020 at 8:03 pm #25637Doctorot

Participantinteresting, so its a secondary pump system just for the cooler. Very tidy bike as well. I see you have it badged as a 865, what pistons are you running? other engine mods? I’m in the middle of a big bore build myself. Nice work. thanks for sharing.

-vic

16th June 2020 at 6:03 pm #25628Doctorot

ParticipantHi Chris. I’m interested in your oil pump setup, are you bypassing the filter? Can you elaborate or show some photos? The last engine I built I had a miss-shift and violent over rev resulting in oil pump cavitation and ended up with rod knock shortly after. I have been considering running a stand-alone electric oil pump to avoid this in the future.

-Vic

31st March 2020 at 5:44 am #25504Doctorot

Participantthanks fellas.

-Gizburn, its a custom ignition cover I designed and cast myself.if you want to see my complete documented build you can find it here> https://kzrider.com/forum/11-projects/598240-saving-a-1980-750-twin?start=0

the casting process starts on page 22

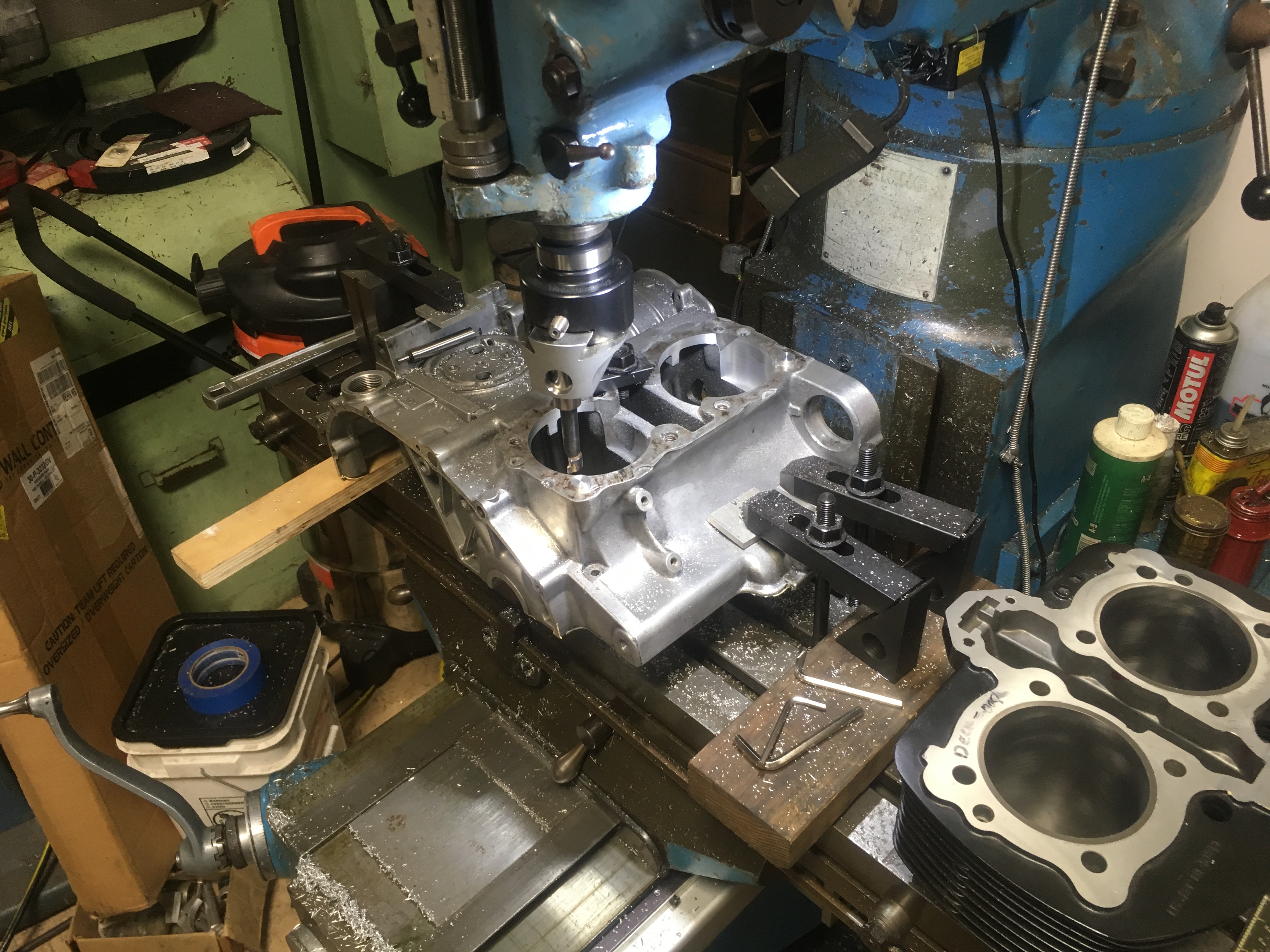

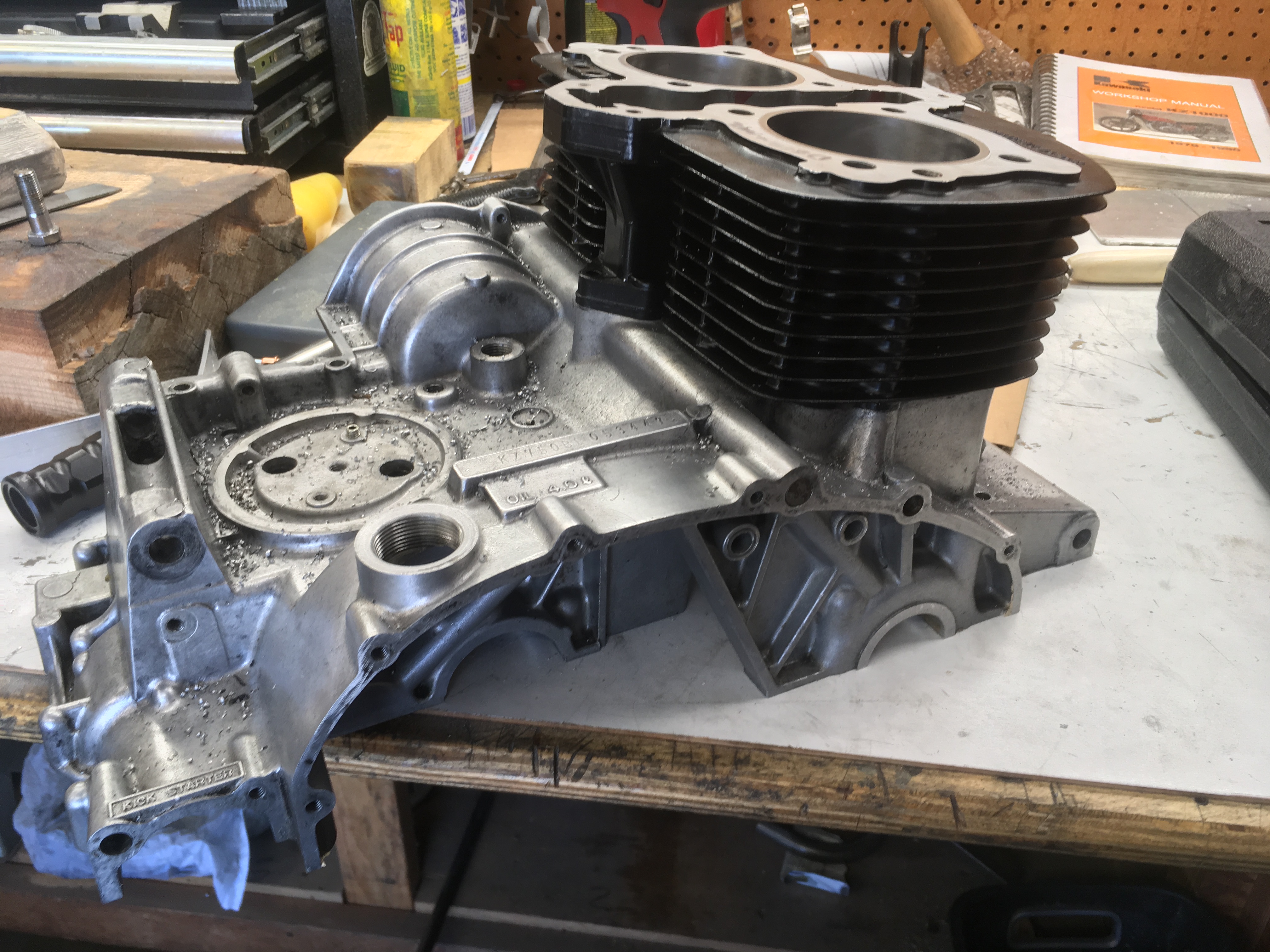

Here are some pics from my ongoing 906cc engine build with custom JE pistons and sleeves. I j bored the crank cases for the larger sleeves this weekend. My machinist is making custom valve guides so that valves with a 7mm stem can be used with 1mm bigger on the intake valve. Also, because he is stuck inside during a quarantine with little else to do, he is giving me his full valve train package heavily discounted. This means titanium valves, titanium retainers, and bee-hive springs, It should rev to the moon!

-

This reply was modified 4 years, 1 month ago by

Doctorot.

13th January 2020 at 3:12 am #25397Doctorot

ParticipantHey Michael, I sent you an email and never heard back. Maybe it went in your spam?

5th December 2019 at 7:23 pm #25375Doctorot

ParticipantHey Michael

thanks for that link, very cool build for sure. i wish google translate worked on handwritten text as it looks like there is a ton of info there. I haven’t been able to find what his static compression was, are you aware if he has written it in the notes?

thanks for sharing

-Vic

3rd December 2019 at 5:12 am #25362Doctorot

ParticipantWow, great build!

So many questions as I am in the process of doing my own 906cc engine! Sorry if it seems overwhelming but its cool to see someone else hot rodding these engines.

The “dry block” – because you are bypassing the oil jets between the cylinder and the head how do you increase oil pressure after the crankcase to the head?

Have you run into cooling issues with the bigger bore?

What is the static compression / cranking compression?

what size exhaust valve? custom valve or custom guide?

What size exhaust tube primary?

Did you port and polish?

you mentioned frame modifications but I think the photos got removed. what did you do there?

Love the look and and track action!

5th May 2016 at 7:52 pm #13226Doctorot

ParticipantThanks for the welcome guys.

I have been in touch with Arias pistons and without sending in my exact requirements they said it would be around $160 USD per piston with a minimum order of 4, discounts for more. That is not bad at all, and I think I may be pursuing this as an option. After reading through Michael’s big bore thread I found the link to LA sleeves, which could be a relatively cheap way to get a new set of sleeves. Hopefully I will have some time in the next month or so to break down the junk motor I have and get some measurements to get a firm quote on the pistons.

This very well could be a pipe dream, but after reading about people re-phasing their XS650’s I’m wondering how insane I would be to attempt to try it. The 750 has a single piece crank so a custom pressed crank would probably be necessary to facilitate this along with re-phased cam and ignition. At the very least I’m going to have the crank lightened and balanced, but a guy can dream can’t he?

-

This reply was modified 4 years, 1 month ago by

-

AuthorPosts